Efficiency is undeniably a must in complex industrial operations. To the latter-mentioned efficiency above, a crucial fact often undermined is the detection and control of air leaks. Whether emanating from a manufacturing facility, a chemical processing center, or even a commercial building, leaks, in whatever form they take, can cause massive energy losses, skyrocketed operational costs, and even safety mishaps. It is a big deal.

Choosing the right air leak detection equipment will aid in identifying and then mitigating these issues. In this blog, we will go through a few critical factors when choosing air leak detection equipment to help you make an informed decision that can prove that time, money, and essential resources are worth it for your business.

Importance of Air Leak Detection

Air leaks are not just annoying problems; they can profoundly affect your operations. Here’s why effective detection of air leaks is essential:

- Cost Reduction: Compressed air is an expensive utility. Even tiny leaks can cause considerable losses in terms of your energy, hence raising the figures on your utility bills.

- Operational Efficiency: Leaks may fluctuate system pressures, impacting the performance of pneumatic tools and machinery, ultimately leading to downtime and underachievement in performance levels.

- Environmental Impact: Reducing air leaks contributes to energy conservation, helping your organization achieve its sustainability goals.

- Safety: in hazardous environments, some air leaks present a significant safety hazard, such as possible explosion or the seepage of toxic compounds.

Types of Leak Detection Equipment

Leak detectors come in various forms, each with its advantages and best-use scenarios. Here are the most common types:

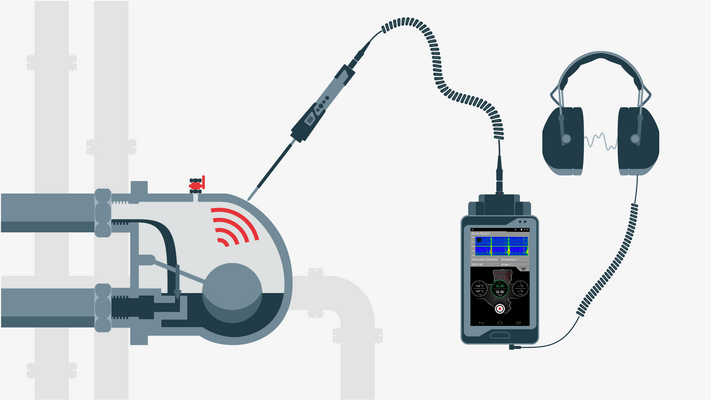

Ultrasonic Leak Detectors

- How They Work: The devices use ultrasonic sound waves to detect high-frequency noise from air leaks.

- The advantages are that it is highly accurate, detects noisy areas, and can pinpoint the exact location of a leak.

- Suitable for industrial environments where precision is key for complex phases.

Infrared Cameras

- How They Work: Infrared cameras create picture images of temperature differences, which may indicate air leakage.

- Advantages: Non-contact detection facilitates the detection of spills at hard-hitting or dangerous places and can also be applied for thermal audits.

- Best For: Large facilities with leaks in elevated or hard-to-reach areas.

Test kits soap bubble

- How They Work: A soapy solution is used at the suspected leak area, and bubbles form at the place where the air is coming out.

- Benefits: Inexpensive and user-friendly.

- It is better for small-scale operations or testing as an initial step and later transitioning to more advanced equipment.

Flow Meters

- Operation: Such devices measure the airflow in a system and indicate the leaks; the difference in expected versus given flow can show the leaks.

- Advantages: Leak size can be quantitatively measured for amount and impact measurements that serve well to monitor effects.

- Suitable for: Continuous monitoring of air systems in extensive facilities.

Ultrasound Imaging Cameras

- How They Work: These cameras work for visual and sound representation into the visual map of the sound to help locate leaks.

- Benefits: Very rapid to apply large areas, visual, and intuitive.

- Best For: Facilities with extensive piping and ductwork.

The Critical Elements That Define Air Leak Detection Equipment Selection

The right air leak detection equipment should be chosen depending on these factors, which should be evaluated based on your needs and environment:

- Sensitivity and Accuracy: Ensure the equipment can sense different sizes of leaks at different pressures. The ultrasonic detectors and acoustic imaging cameras are typically susceptible and accurate.

- Ease of Use: Also, consider the user interface: how much training needs to be given to make the equipment operative? Infrared cameras and soap bubble test kits would usually be user-friendly for the inexperienced, while ultrasonic detectors on them would likely require some training.

- Environment and Applications: It would, therefore, depend on the environment where the equipment will be used. Ultrasonic detectors are ideally situated in noisy industrial environments. Infrared cameras are best in hazardous areas or areas a person cannot easily access.

- Weigh the upfront cost of the equipment: This should be done against potential savings from prevention through the detection and repair of leaks. Although super-high expenses could be incurred for some equipment items, for example, flow meters and acoustic imaging cameras, their benefits could be equally enormous.

Maintenance and durability

Look into the equipment’s durability, maintenance, and support availability. Equipment used in harsh industrial environments should be rugged and require little maintenance.Modern air leak detection equipment is often fitted with the capacity to record and analyze data, which is vital if leaks are to be traced for ongoing maintenance and efficiency. Make sure that whatever equipment is chosen can work with present operating systems.

Steps to Implementing Air Leak Detection

Once you select the proper equipment, you must build an effective air leakage detection program. Here is how to do it:

- Perform a Baseline Audit: Conduct an initial audit. This identifies the current state of your air system and sets a foundation against which to measure future improvements.

- Train Your Team: Ensure your maintenance team is appropriately trained on using detection equipment and understand the importance of regular leak detection.

- Regular Inspections: Schedule periodic inspections using the detection equipment to help locate and repair the leaks immediately.

- Document and Analyze Data: Document any leak identified in detail, every repair carried out, patterns observed, etc. Use this information for operational system optimization and to identify any repetition in the issues.

Picking the proper air leak detection equipment increases your high efficiency, safety, and sustainability in operation. This means that understanding different kinds of detection equipment will enable one to make an informed decision on the efficiency of an individual’s needs, leading to costs that will save a lot in operations. An effective air leak detection program guarantees that the money invested in detection equipment will improve and save more for the future. Remember, the success of managing leaks equals proactive and constant efforts to maintain and optimize your systems, not only detection. Investment in the right equipment and adoption of best practices will go far in realizing excellent performancelongevity and running an air system more effortlessly and productively.